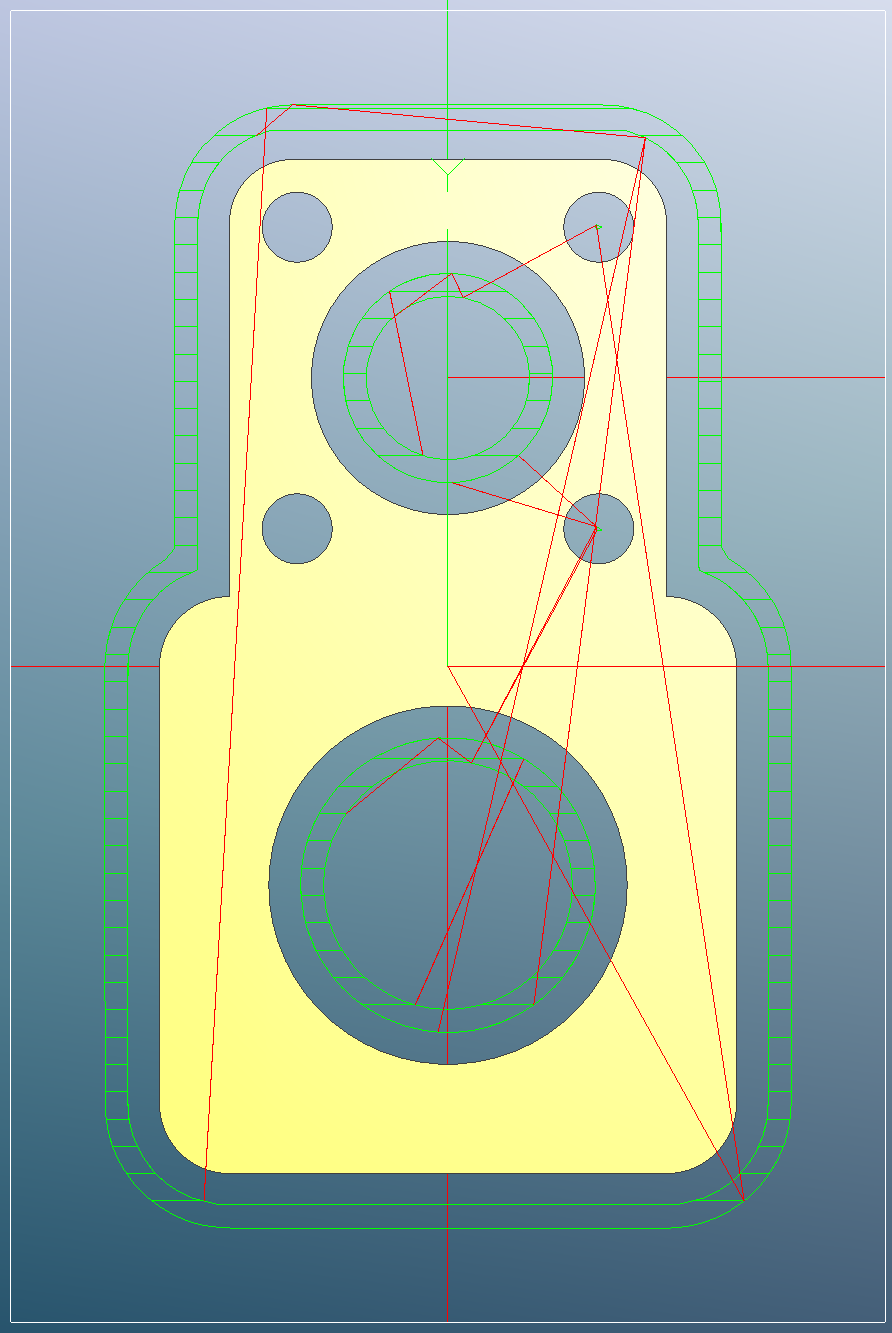

When the end mill is just too close to the hole size and machining tolerance, MeshCAM doesn’t dive in and handle it. I just don’t try to cut a “hole” that close to an end mill diameter. I follow a rule that I do not expect MeshCAM to dive into a pocket (hole) unless the pocket is at least 10% bigger than the end mill I’m using. It won’t dive into a pocket/hole - it’s “not there”. If the end mill is just too close the characteristics determined for the feature and the tolerances being used it will not machine it. This probing around is not a perfect process and tolerances are involved. It offers features for processing raw data produced by 3D digitization tools/devices and for preparing models for 3D printing. It provides a set of tools for editing, cleaning, healing, inspecting, rendering, texturing and converting meshes. It may be smart enough to recognize it as a circular feature and use G02/G03 (circle G codes) or it may not. MeshLab the open source system for processing and editing 3D triangular meshes. Compare features, ratings, user reviews, pricing, and more from MeshCAM competitors and alternatives in order to make an informed decision for your business. SourceForge ranks the best alternatives to MeshCAM in 2021. When it finds a void (all the way through or not) it probes around to determine the characteristics of the feature (hole/pocket). Compare MeshCAM alternatives for your business or organization using the curated list below. It “feels out” (follows/probes) the surface. MeshCAM does not know there are holes - it follows the mesh (the surface) and hence its name.

Randy nailed it! Love the blind person and cane analogy. A notch or rip should not be made in a stud wall. Limit the length of notches to 1 / 3 of the joist's depth. The pencil finishing will clear out the bottom of the outlines that the waterline usually won’t (even if the stepdown is an even divisor of the thickness). Notches should be no deeper than 1 / 6 the depth of a joist. Set a stepdown for the waterline that you are comfortabvle taking full-width with the cutter. If it is in phase, it will “see” the holes, if it is out of phase, it won’t “see” the holes.įor a 2.5D part (only vertical walls) you’re better off not roughing, and just doing waterline + pencil finishing. The roughing has a stepover of its own that may or may not be in phase with small holes. Without enough room to swing the cane, the person doesn’t know that an opening is big enough to fit in. As I’ve said before, I don’t know the inner workings of MeshCAM but I picture it as a blind person with a cane. MeshCAM does not “know” there is a hole when it’s calculating milling toolpaths. Its #1 job is to not gouge the workpiece, so it errs on the side of staying farther away than getting too close. Your holes will be too small and your outlines be too large, only using roughing. It’s really designed only to clear out bulk material and will not be accurate to the surface in its toolpaths, even specifying a small Stock to leave. Roughing uses a different toolpath calculation than finishing.

0 kommentar(er)

0 kommentar(er)